Contrary to public belief, the 330 mm OPf Mle 1935 shell was not classified as a Semi-Armor Piercing type of ammunition. Historically, the Dunkerque class was designed to counter ships like the Graf Spee, which were lightly armored compared to other capital ships. One theory suggests that the 330 mm OPf shell was designed as SAP to fulfill this purpose. There are currently two claims that attempt to support the classification of the 330 mm OPf shell as SAP: the burster cavity was too large and the hardened cap was too thin compared to typical AP shells. However, additional historical and technical context disproves these claims and instead suggests that the 330 mm OPf shell was designed as AP. The historical context will be first established before addressing each of these claims.

Historically, ships before the République class of pre-dreadnought battleships in 1909 used a wide variety of shell types, including capped AP, semi-AP, cast-iron, Common, HE, and Shrapnel. With the République and Démocratie class, the French simplified the ammunition choices to AP and semi-AP. Not long after these changes, it was decided to combine the functions of AP and semi-AP into a single type of AP round with a higher-than-average explosive charge. This unique type of shell was first used by the Dantons and continued through the Courbet, Bretagne, and Dunkerque classes. The new shell was designated “Obus de Perforation de Rupture Coiffé”, which corresponded to the English term “armor-piercing-capped”.

The omni-purpose shell was made possible by the use of a variable delay fuze, which determined the time delay based on shell deceleration. Theoretically, this would reduce the probability of over-penetrations against a lighter armored unit while preserving the ability to penetrate heavier plating. Not much is known about this unique French type of fuze. It appeared to have been effective in operation after issues with earlier versions of the fuze were resolved.

Other navies have attempted to replicate its functions with generally little success. For instance, the US Navy developed the Mark 11 base detonating fuze in 1937 with a variable delay time of 0.003 to 0.025 seconds using a completely different mechanism to achieve a similar effect. However, the Mark 11 fuze had reliability issues that were especially a problem at sharper angles of impact.

The first claim in favour of SAP states that the burster cavity was too large for an AP shell, with the explosive filler taking up to 3.6% of the shell weight. However, this statement only holds true when compared to certain AP shells like the American 406 mm AP Mark 8 Mod 6, which had around 1.5%. Other French shells such as the 305 mm and the 340 mm which were designated as AP had 3.93% and 4% of the shell weight in filler respectively. Furthermore, a comparison to earlier British shells showed that a lot of older AP rounds typically had around 3% (see table below).

The 3.6% figure for the 330 mm OPf shell is also much less than other large caliber SAP rounds, 4.9% for the 320 mm Granata Perforante and 11.7% for the 12-inch SAP patt.1911, while only marginally more than older British AP rounds. It is clear that based on explosive filler percentages alone, that the 330 mm OPf shell resembles AP more than semi-AP.

| 330 mm OPf Mle 1935 | 381 mm Mk.1a APC | 13.5 inch APC Mk.Ia | 320 mm Granata Perforante | 12-inch SAP patt.1911 | |

|---|---|---|---|---|---|

| Type | SAPCBC | APC | APCBC | SAP | SAPCBC |

| Shell Weight (kg) | 560 | 871 | 635 | 475 | 470.9 |

| Filler Weight (kg) | 20.2 | 27.4 | 20.2 | 23.4 | 55.2 |

| Filler Weight % | 3.61% | 3.15% | 3.18% | 4.92% | 11.72% |

| Ships | Dunkerque | Barham | Marlborough Iron Duke Queen Mary | Duilio Cavour Novorossiysk | Poltava Mariya Marat Kommuna |

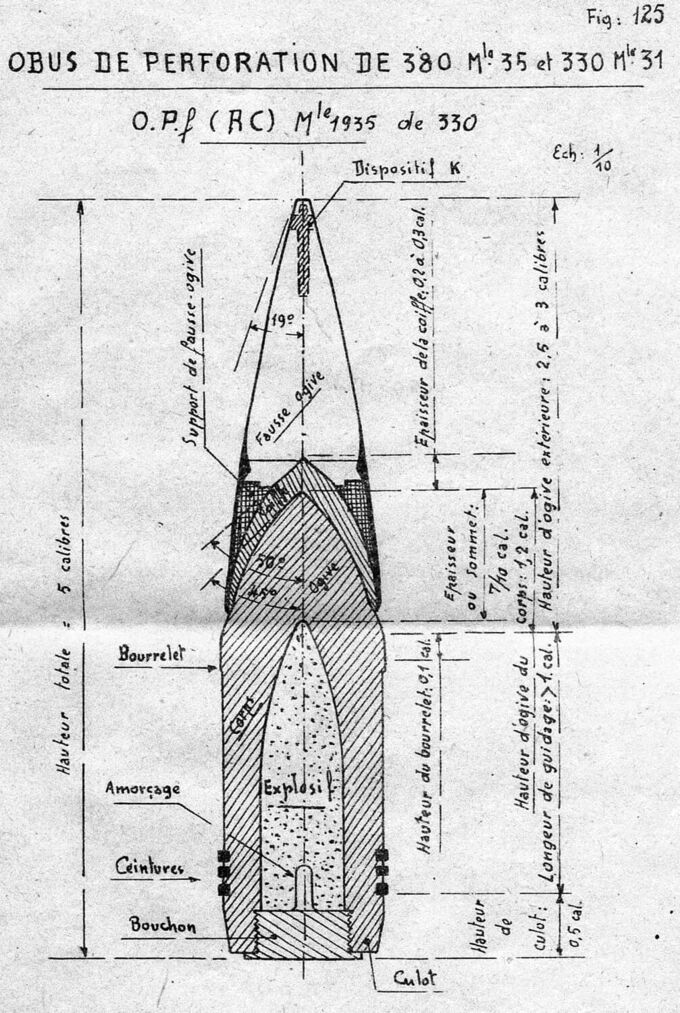

The second claim states that the hardened cap was too thin for an AP shell, thus greatly reducing its penetration capabilities. The original sketch of the 330 mm OPf shell labels the thickness of the hardened cap between 0.2 and 0.3 calibers (see Fig 4). Since measurements in calibers are multiples of the shell diameter, 0.2 and 0.3 calibers multiplied by 33 cm would translate into 6.6 and 9.9 cm. This means that according to the original sketch, the hardened cap would have a minimum thickness of 6.6 cm and a maximum of 9.9 cm.

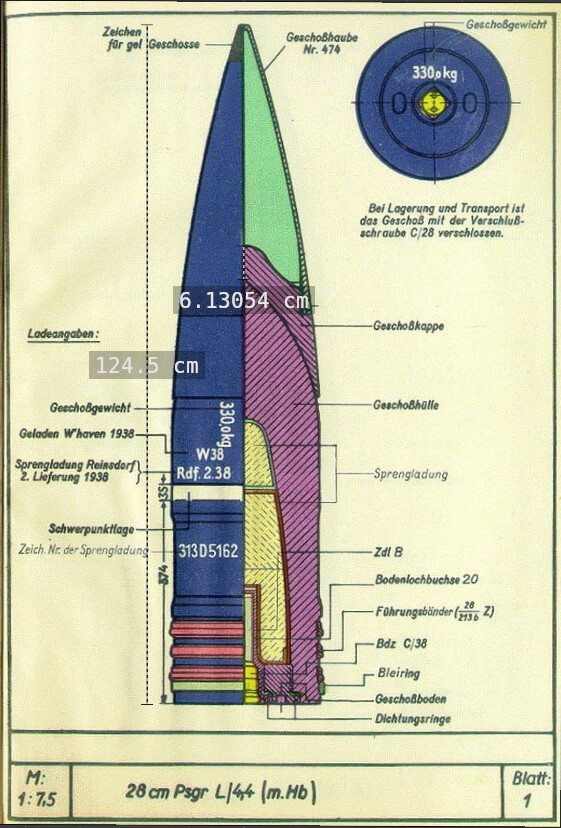

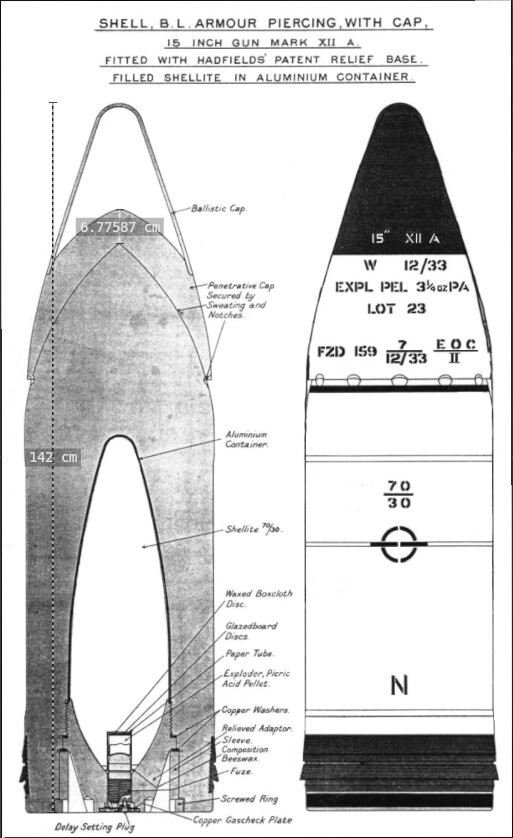

A quick measurement of other contemporary AP shells shows that this range of values is well within AP territory (see Fig 4 & 5). The cap thickness was measured as 6.1 cm for the 283 mm Psgr. L/4.4 APCBC and 6.8 cm for the 15-inch 4crh Mark XIIa APC. The 330 mm OPf shell already exceeds the German round by its minimum cap thickness alone while quickly approaching the much larger British 15-inch round. Since the known minimum hardened cap thickness of the 330 mm OPf shell is already comparable to other contemporary shells, the claim that the hardened cap was too thin for an AP shell is completely incorrect.

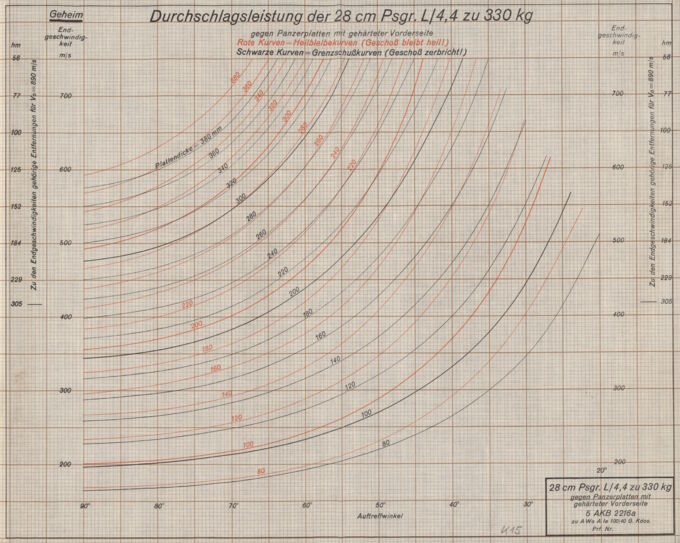

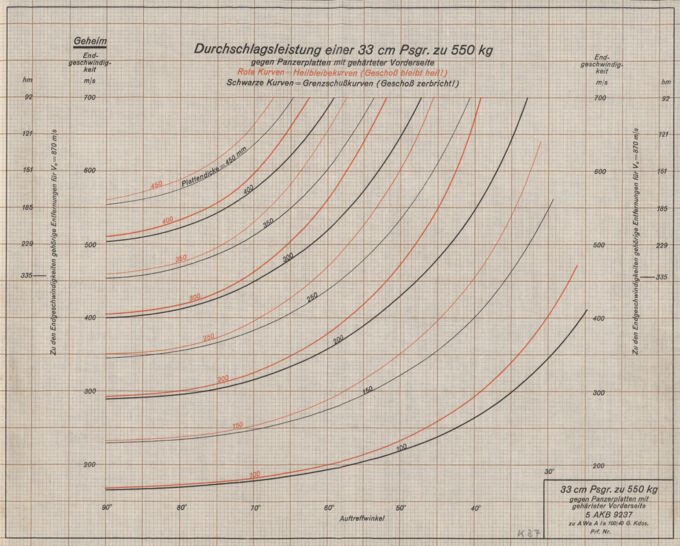

Shell penetration tables obtained from the Bundesarchiv also show that the 330 mm OPf shell has significantly higher penetration capabilities to that of the 283 mm Psgr. L/4.4 APCBC. According to the tables, the 330 mm shell is able to penetrate a 450 mm plate at 0 degrees from a distance of 15,100 meters while the 283 mm shell is only able to go through 340 mm (see Fig 6 & 7). This should not be surprising as it was previously established that the minimum armored cap thickness of the 330 mm OPf shell exceeds that of the German round. Combined with the properties of a heavier shell that travels at a relatively fast velocity, the penetration performance of the 330 mm shell on paper would be closer to that of an AP shell rather than semi-AP.

In conclusion, if you were to say that the 330 mm OPf Mle 1935 shell was a semi-AP round, you would be technically half right, but not quite there yet. By design, it could act like a semi-AP round with a shorter fuze delay when it struck lighter plating, but as far as the French were concerned, it was classified as AP as it was designed to penetrate heavier plating. In addition, the filler weight percentage may have been slightly higher than older AP rounds, but it still remains far lower than any round that is classified as SAP. Finally, the minimum thickness of the hardened cap is on par with other AP shells from foreign nations. All of this points towards a definite classification of the 330 mm OPf Mle 1935 shell as AP.

Sources

- Friedman, Norman. Naval Weapons of World War One: Guns, Torpedoes, Mines, and ASW Weapons of All Nations: An Illustrated Directory. Naval Institute Press, 2011.

- Jordan, John, & Dumas, Robert. French

Battleships, 1922-1956. Naval Institute Press,

2009.

- RH 8/3521, Allgemeines zur Munition. Bundesarchiv.