US Bombs General Information

Contents

General Information

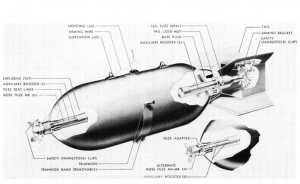

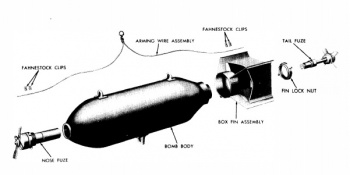

A bomb is a specific type of ammunition which is designed to be dropped from an aircraft while in flight. The bomb itself typically is made up of a metal container which is filled with explosives or chemicals, a stabilizing device to allow for accurate aiming, a mechanism to initiate an explosive train to detonate the device at the target and any appropriate safety devices to allow for the safe handling of the munition. Bombs manufactured for the U.S. are typically made up of several components of which include:

- Bomb body – an aerodynamic metal container with a rounded (ogival) nose and a tapered tail. The bomb body contains the explosive filler and can be constructed from welding several pieces together or casting one piece.

- Stabilizing device – a device attached to the tail end of the bomb crafted from sheet-metal which stabilizes the fall of the bomb and allows for accurate dropping on targets. These can include box type, conical or stream-lined type or retarding type.

- Box type: Composed of a fin sleeve with sheet-metal blades joined to the fin sleeve, forming a box-like assembly. Support struts are typically added to strengthen the fin box.

- Conical or stream-lined: crafted cone-shaped body with metal blades joined directly to the body to create a low-drag or stream-lined configuration.

- Retarding type: Can consist of streamers, parachutes or folded blades which open in an umbrella type fashion which induces high-drag, slowing the fall of the bomb.

- Fuze – a mechanism which causes the main charge to explode. A bomb may have a fuze in the nose of the bomb, one in the tail or a fuze in both.

- Arming-vane assembly – A small propeller device with sheet-metal blades attached to specific mechanical fuzes and activate after the bomb is released from the aircraft and the safety wire is pulled free. The spinning propeller will cause the fuze to arm itself in preparation for detonation at a target site depending on mission requirements.

- Safety device – one or two strands of arming wire attached to a swivel loop which prevents the arming of fuze until withdrawn.

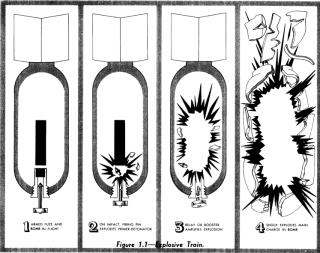

Explosive Train

When it comes to bombs, the explosive train is the series of events which take place from arming the bomb to its detonation sequence. Typically when a bomb is dropped with the intent of destroying a target, it is released from its carrying aircraft. During the initial release and drop, an arming wire assembly which is secured to the releasing mechanism will slip out from the bomb's fuzes (nose, tail or both if installed). As the bomb drops, the fuze propellers are free to spin and in doing so, arm the fuzes after a certain amount of time. If the bomb impacts with the ground or an object before the fuze has a chance to arm, it will not explode. Once the fuzes arms, the bomb is ready to detonate. Depending on the type of bomb and the type of fuzes, the bomb may explode on contact with the ground or an object or may impact first and explode with a delayed explosion. The steps of an explosive train:

- Safe bomb

- Arming wire assembly removed

- Fuzes arm

- Bomb impacts, triggers firing pin

- Primer detonator explodes

- Chain reaction detonates a relay or booster

- Main explosive filler is detonated, exploding the entire bomb

Classification of bombs

- Armor-piercing bombs (AP)

- AP bombs are thick-walled with a heavy steel nose and a tail fuze. The purpose of these bombs is to penetrate armoured and hardened targets and then explode with fragments once inside of the hardened structure wreaking havoc with less hardened internal components (below decks on the ship, engine rooms, crew quarters, munition stores, and hardened bunkers performing the same role). Approximately 30% of the bomb is explosive filler. Unlike a general-purpose or demolition bomb, AP bombs don't rely on the explosive power of the blast to damage the exterior of a structure, but instead, utilize the terminal velocity and weight of the bomb to punch through a hardened structure where then a fragmenting explosion will be able to damage lesser or unprotected assets.

- Semi-armor-piercing bombs (SAP)

- SAP bombs typically are thickly walled and will utilize only a tail fuze. The nose fuze hole is usually closed with an armour-piercing plug. The purpose of these bomb types is to penetrate armoured and hardened targets prior to detonation, allowing for the explosive charge to reach lesser protected areas before exploding. Approximately 30% of the total bomb weight is composed of explosive filler.

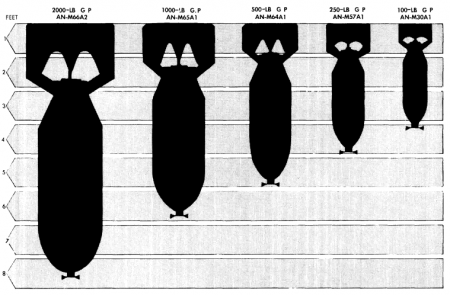

- General purpose bombs (GP or GPHE)

- GP bombs are utilised for a majority of the bombing operations against targets which require some penetration. These bombs typically have thin walls and approximately 50% of these bombs are composed of explosive filler. GP bombs can be configured with both nose and tail fuzes depending on mission requirements and redundancy. Three classifications include old-series (100 to 2,000 lb bombs), new-series (750 to 3,000 lb bombs) and low-drag (250 to 2,000 lb bombs) depending on their configuration.

- GP bombs are utilised because of their blast effect, fragmentation and deep-mining effects. The function of the bomb is determined by the fuze type installed. Explosive fillers can include Tritonal, Amatol, TNT, Comp B, H6 and in special cases HBX.

- Aircraft depth bombs (AD)

- AD bombs are primarily used against underwater targets, however, they can also be used as a GP bomb. AD bombs are composed of approximately 70% of the bomb's total weight. These bombs have a flat nose which prevents them from skipping on the water when dropped from low altitudes. Hydrostatic fuzes are utilised in the tail of the bomb and functions to arm at a specific depth as opposed to impact.

Bomb Comparison Chart

| U.S. Bomb Comparison Chart | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bomb weight | Modified Mark | "M" Series | Navy "Mk" Series | "AN" Series | "AN G.P." Series | "AN G.P. A1" Series | "AN G.P. A2" Series | Low Drag G.P. Series |

| 100 lb | Mk.I M.IV | M30 | Mk.1 / Mk.4 | AN-M30 | AN-M30 | AN-M30A1 | - | - |

| 200 lb | Mk.I M.II | - | - | - | - | - | - | - |

| 250 lb | - | M57 | - | AN-M57 | AN-M57 | AN-M57A1 | - | Mk 81 |

| 300 lb | Mk.I M.III | M31 | - | - | - | - | - | - |

| 500 lb | - | M43 | Mk. III / IX / XII | AN-M43 | AN-M64 | AN-M64A1 | - | Mk 82 |

| 600 lb | - | M32 / M62 | - | - | - | - | - | - |

| 750 lb | - | - | - | - | M117 | M117A1 | M117A1E2 | - |

| 800 lb | - | M61 | - | - | - | - | - | |

| 900 lb | - | M60 | - | - | - | - | - | - |

| 1,000 lb | Mk.III M.I | M44 / M52 | Mk 3 / 5 / 9 / 13 / 36 | AN-M44 | AN-M65 | AN-M65A1 | - | Mk 83 |

| 1,100 lb | - | M33 | - | - | - | - | - | - |

| 1,400 lb | - | M63 | - | - | - | - | - | - |

| 2,000 lb | Mk. I M. III/IV/V | M34 | - | AN-M34 | AN-M66 | AN-M66A1 | AN-M66A2 | Mk 84 |

| 3,000 lb | - | - | - | - | M118 | M118E1 | - | - |

| 4,000 lb | - | - | - | - | AN-M56 | AN-M56A1 | - | - |

Model Numbers

Model numbers are assigned to allow for distinguishing between different designs of the same type as a standardized item.

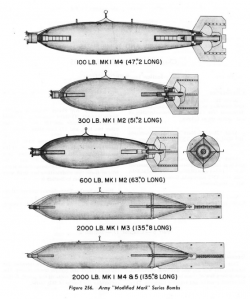

- US Army "Modified Mark" Series

- Equipment designated by the Army prior to 1943 by the letters "Mk" followed by a Roman numeral. If the original design was changed then the mark number was followed by a modify number or the letter "M" and an appropriate roman numeral (example Mk. I M. III). By the start of World War II, these bombs were considered unsatisfactory for wartime purposes and were rendered obsolete, however, a few were retained for training purposes. The explosive filler in the Mk series bombs was 100% T.N.T. The Mk series bombs included:

- Mk. I M. IV (100 lb)

- Mk. I M. II (200 lb)

- Mk. I M. III (300 lb)

- Mk. III M. I (1,000 lb)

- Mk. I M. III (2,000 lb)

- Mk. I M. IV (2,000 lb)

- Mk. I M. V (2,000 lb)

- US Army "M" series

- Equipment designed by the Army will have the model designation consist of the letter "M" followed by an Arabic numeral. Modifications of the original equipment design will be followed by a letter "A" and appropriate Arabic numeral to follow (example: M4A1). Prior to the Army-Navy standardization board in 1941, these bombs were considered "Demolition High-Explosive" bombs, however, this type of bomb after the standardization was reclassified to "General Purpose" (G.P.) or "General Purpose High-Explosive (G.P.H.E)." These bombs were filled with either 50/50 Amatol or 100% T.N.T. Due to the hygroscopic nature of Amatol when used, T.N.T. surrounds were placed around the booster sleeves to seal the Amatol off from any moisture. Army "M" series bombs included:

- Other bombs with "M" designation, but are not of the "M" series (also obsolete):

- M62 (600 lb) A.P.H.E.

- M61 (800 lb) A.P.H.E.

- M60 (900 lb) A.P.H.E.

- M52 (1,000 lb) A.P.H.E.

- M63 (1,400 lb) A.P.H.E.

- M5 (30 lb) Fragment bomb

- US Navy "Mark" or "Mk" Series

- Navy designed items are designated by either the word "Mark" or the abbreviation "Mk" followed by an arabic numeral. Modifications to the original designation utilise "Mod" followed by an arabic numeral (example: Mk 4 Mod 2).

- Explosive filler is 100% T.N.T.

- G.P. Mk 1 (100 lb)

- G.P. Mk 4 (100 lb)

- G.P. Mk 12 Mod 2 (500 lb)

- G.P. Mk III Mod 1 (500 lb)

- G.P. Mk XII Mod 1 (500 lb)

- G.P. Mk IX (500 lb)

- US Army-Navy "AN" series

- Specific equipment which was standardized for use by both the Army and the Navy took place in 1941. These items which were transitioned are designated with the letters "AN". Other changes were made during the standardization other than the designation which included adding a third suspension lug at the centre of gravity on the opposite side of the already-in-place dual lugs which allowed the ordnance to be hung from British aircraft. Baseplates within the bomb had the female plug changed to a male plug, increasing the strength of the bomb when used against low-angle penetration targets. All general-purpose bombs are now considered "High-Explosive" bombs. Further designation refinement changed from just general-purpose bombs to "AN G.P." which allowed them to then be used on anti-submarine work.

- AN-M64, AN-M65 and AN-M66 bomb's explosive filler was 50/50 Amatol until the supply of T.N.T. was ample enough in 1943 to become the main explosive filler. Approximately 25% of these bombs were also filled with Composition "B" as their explosive filler. Other explosive fillers introduced were Tritonal, Explosive "D" and Picratol.

- A1 Modification – The A1 modification consisted of two steel pins which locked the baseplate to the main filling. This prevented removal of the baseplate once the explosive filler was added to the bomb body. The adapter boosters within the bomb were also modified (M102A1 and M115A1) which consisted of a hole through the adapter booster and a groove in the threads of the baseplate which received a locking pin. This locking pin shipped with all anti-withdrawal tail fuzes. Once inserted the fuze could not be removed without detonating the bomb.

- A2 Modification – Typically a lower concentration of explosive filler between the A2 and A1 versions and has a thicker nose.

- G.P. H.E:

- AN AP bombs:

- AN/M58 / A1 / A2 (500 lb)

- AN/M59 / A1 / A2 (500 lb)

- M103 (2,000 lb)

- AN/Mk.33 (1,000 lb)

- AN/Mk.1 (1,600 lb)

- Modern Mark 80 General Purpose bombs

- Early on, bomb shape with the ogival nose and tapered tail was sufficiently aerodynamic enough when attached to external pylons of an aircraft, however as aircraft flew faster and carried more ordnance, it was imperative to take another look at more efficient aerodynamics. This study resulted in low drag general purpose bombs being developed which were the same weight as their predecessors, however, the bombs were longer in length and smaller in diameter which resulted in increased aerodynamic efficiency for the aircraft carrying the ordnance. One complication resulted for fighter and attack aircraft occurred when using these low drag bombs came to light when these bombs were dropped from a low attack altitude and hit their target, exploding before the attacking aircraft could clear the area. To overcome this obstacle, kits were created to modify the low drag bombs which when installed on their rack en route to the target were efficient and low drag, however, when released either bladed plates extended or parachute type devices deployed which retarded the fall of the low-drag bombs, converting them to high-drag bombs allowing the low-altitude attacking aircraft to clear the target area before the bombs exploded. The U.S. Navy and Marines added a thick ablative fire-retardant coating (upwards of 40 lb added to the total weight of the bomb) which delayed ship-board explosions in the event of a ship fire and allowed firefighters extra time to control and extinguish a fire before the bombs would start exploding. Low drag general purpose bombs (LDGP) include the following:

External Links

- Department of the Navy, Bureau of Ordnance. (1955). Ordnance Pamphlet 1280 - Aircraft Bombs. https://bulletpicker.com/pdf/OP 1280, Aircraft Bombs.pdf

- Department of the Navy, Bureau of Ordnance. (1947). Ordnance Pamphlet 1664 - U.S. Explosive Ordnance (Vol. 2). https://bulletpicker.com/pdf/OP 1664 US Explosive Ordnance, Volume 2.pdf

- Departments of the Army, the Navy and the Air Force. (1966). Technical Manual 9-1325-200 - Bombs and Bomb Components.https://bulletpicker.com/pdf/TM 9-1325-200, Bombs and Bomb Components.pdf

- U.S. War Department. (1930). Technical Regulation s No. 1370-G - Miscellaneous Ammunition - Bombs for Aircraft. Washington DC: War Department.https://www.scribd.com/doc/76610337/TR-1370-G-US-Ammunition-Bombs-for-Aircraft-Oct-1930