Hydropneumatic suspension, or controlled suspension, is a wheel suspension system that allows a vehicle’s ground clearance to be adjusted. With these types of systems, vibrations are dampened by specially designed hydropneumatic shock absorbers, while the compression force is transmitted by fluid to each shock absorber’s pneumatic receiver chamber.

The hydraulic systems of modern hydropneumatic suspension systems are controlled electronically. However, these types of systems do not necessarily require an electronic control system.

Description and usage

Hydropneumatic suspension can increase a tank’s vertical aiming angles (elevation and depression) and also allow the tank to rise slightly above obstacles to fire. This system gives vehicles more versatility in battles, as the suspension can be used to take advantage of the terrain. For example, a few extra degrees of gun depression can be achieved by adjusting the suspension forward, causing the vehicle to tilt downward.

Note that a vehicle’s hydropneumatic suspension system cannot be damaged (the various parts of the system are not modelled), and its operation does not depend on the battery charge of the vehicle. However, disabling the engine of a vehicle will make the suspension inoperable until the engine is repaired.

Different types of hydropneumatic suspension

There are three main types of hydropneumatic suspension, each operating differently: left-right, front-back, and up-down. For example, the Stridsvagn 103 uses a front-back system, letting it tilt forward and backward but not side to side. A left-right system allows for the vehicle to be tilted towards the left or right, and a up-down suspension only allows for the vehicle to be raised or lowered.

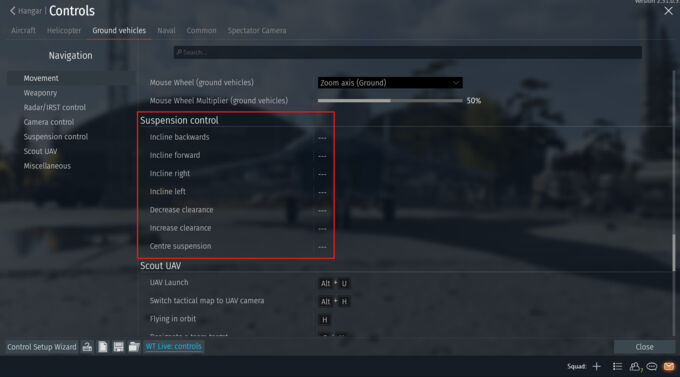

Keybinds for suspension controls

By default, keybinds for controlling hydropneumatic suspension are not configured. To add them, go to the “Controls” section.

Historical background

The idea of oil and air hydropneumatic suspension systems was invented by Paul Magès, who was an employee at Citroen during World War II. This technology was eventually integrated into the Citroën DS automobile and unveiled at the Paris Motor Show in 1955. Thanks to this suspension, the Citroën DS' ground clearance did not depend on the load while also allowing for the height of the clearance to be manually adjusted. The ride of the car was also exceptionally smooth compared to other vehicles of the era.

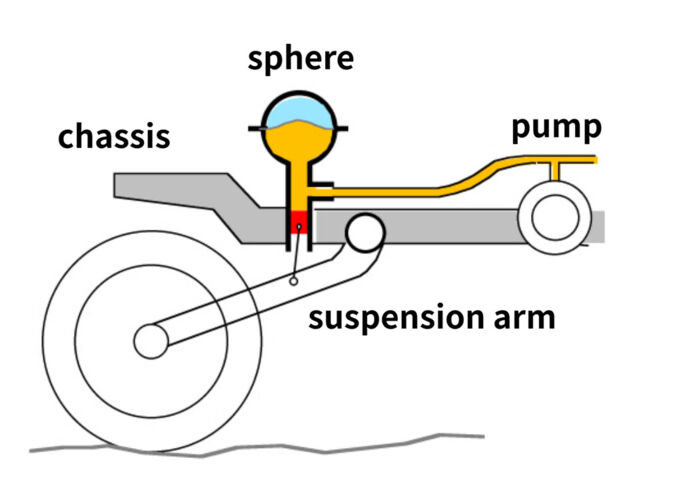

In vehicles equipped with hydropneumatic suspension, each wheel is connected to a hydraulic cylinder filled with oil or hydraulic fluid, which is in turn connected to a sealed unit containing gas behind a flexible membrane. When the wheel hits a bump, the suspension arm connected to the wheel pushes oil or fluid into the sphere and forces the nitrogen gas to compress. The gas compression effect is what provides the “spring” effect.

MBT-70 project

One of the first military programs that concerned the usage of hydropneumatic suspension was the MBT-70 project, which was a collaborative development program between the United States and West Germany to produce a new main battle tank. The program specifically called for the usage of a “newly designed hydropneumatic suspension”, which would have allowed for the tank to depress its main armament even further than the limit of -10°.

Ultimately, the results of the MBT-70 project were never realized due to it being shelved. Multiple disagreements between West Germany and the US over certain aspects of development and the fact that the program was massively over budget contributed to the project’s closure.

Strv 103

The Swedish Stridsvagn 103 was the first tank with a hydropneumatic suspension system to be mass produced. Each of the Strv 103's eight road wheels (four on each side of the tank) were equipped with a gas-hydraulic suspension unit. The front and rear units were also connected to allow for the tank to tilt towards the front or back.

Due to the Strv 103's gun being rigidly fixed to the hull with no horizontal or vertical drives, the adjustable suspension allowed for the elevation or depression of the gun.

The suspension could also be locked in place to make it rigid, providing a stable platform for the gun when firing. This was necessary due to the Strv 103 being unable to utilize a conventional stabilized turret.

Modern day usage

Some modern main battle tanks like the Japanese Type 90 and Type 10 MBTs use hydropneumatic suspension systems due to the added versatility and advantages of having such a system. Despite these benefits, however, other notable MBTs like the M1 Abrams and Leopard 2 use traditional torsion bar systems due to the added complexities of adding and maintaining hydropneumatic suspension units.